|

What is

Stonehenge?

The three rings of stones

which make up the UMR-Stonehenge were inspired by a monument created

in Southern Britain some 5,000 years ago.

This original Stonehenge

stands on a hillside about 8 miles north of the town of Salisbury.

It was begun, archaeologists now believe, as a simple device by

which the seasons could be foretold, using the position of the moon,

relative to four stones and a ditch.

This had become necessary at

that time since the local tribes had changed from hunting to farming

as a way of providing food and needed a means of telling when they

should plant their crops.

Figure 1. The

"original" Stonehenge on Salisbury Plain, England.

There is, however, some variation in the

path of the moon over the sky, from year to year, so that this first

attempt at a calendar was not very accurate.

Additional stones were

added over the centuries to form complete circles, around a central

altar stone, as the leading shaman or priest-equivalent (this was

long before the Druids) tried to make a more accurate calendar. It

was not, however, until the site was changed from marking the

position of the moon to that of the sun that the "calendar" finally

became accurate enough to pinpoint exact dates.

By this time the importance of the site had been shown by the use of

very large stones to form two of the stone circles. It is these two

circles, the outer sarsen ring, and the inner trilithon ring which

are the features most people consider when they talk of Stonehenge.

The outer of the two rings comprises 30 upright stones which stood

15 ft high was capped by a set of lintels notched to fit on the

uprights and arranged to form a continuous walkway around the top of

the stones.

Within this ring the 5 trilithon (three-stone) ring stands, around

the altar with the highest, or great trilithon, located behind the

altar and standing some 28 ft high.

Less prominent, but more

necessary to tell the time between the major days when the sun shone

in alignment with the great stones, a smaller bluestone ring of

single stones was erected. There were 19 of these and it is likely

no coincidence that 19 multiplied by 19 equals 361 which, if one

adds 4 days for fasting, celebration and recovery to mark the end of

the year, gives us a calendar.

There is a reference in some of the

ancient Gaelic legends to days "when time stands still." (The

Bahai

faith has also, quite independently, developed such a calendar.)

An

alternative explanation has been proposed by Gerald Hawkins, who

suggests that these nineteen stones are related to the 18.61 year

cycle during which the moon-rise position will oscillate along the

local horizon.

This then, very simply, was the basic model from which the UMR-Stonehenge

idea was developed. The word stonehenge itself means "hanging stone"

(for more information see bibliography) from the lintels that cap

the rocks.

Back to Top

Why Build a

Stonehenge Here?

The University of Missouri-Rolla is a leading University in

engineering, computer science and mining technology. When Dr. Joseph Marchello became Chancellor, he came from the University of

Maryland, where he had helped found the Center for Archaeo-Astronomy.

This interest, and the unique combination of expertise at

Rolla,

especially that of Dr Joseph Senne, then Chairman of Civil

Engineering and a local astronomer, and the UMR high pressure

waterjet group, led him to propose construction of the project to

the alumni, who funded it.

Figure 2. (From the

left) Dr Senne, Mr Bevan, Dr Carlson and Chancellor Marchello.

Back to Top

What is the

Stonehenge built from and where did it come from?

The UMR-Stonehenge is made of

granite which was quarried in Elberton, Georgia. The rock is a hard

igneous stone, which is commonly used for monuments. Elberton,

Georgia is a major center of the American Granite Quarrying

industry.

This happened partially because, in 1978, the National

Science Foundation funded a study to find better ways of quarrying

granite in the United States. One of the ways that were tested was

through the use of high pressure waterjets and Dr. Summers of the

UMR RMERC was one of the panelists who worked on that program.

It is interesting to note that one of the quarries in which the

original testing of waterjetting was carried out in 1978, later

served as the source rock for the granite which forms the UMR

Stonehenge. The work was subcontracted from the Elberton Granite

Association to Georgia Institute of Technology. UMR carried out a

field demonstration for this consortium during the week of November

27, 1978.

Cutting rates of almost 24 sq.ft/hour were achieved in the

overlying "sap" stone, and a slot was cut some 18 ft long and 42

inches deep. In the solid higher quality stone cutting rates were

around 12 - 15 sq.ft/hour.

Figure 3. Original

NSF panel:

Dr. Summers (UMR)

Mr. Tessner (Ga Tech)

Mr. Stengel

(Northwest Granite)

Mr. Ralph (Barre,

VT); 2nd row Mr. Tyler (Century Granite)

Dr. Hakala (NSF); Mr.

McGarity (Harmony Blue)

Mr. Harper (Apex

Granite)

3rd row Mr. Wright (Ga

Tech)

Mr. Coggins (Coggins

Granite)

Mr. Kelly (EGA)

Back to Top

Why didn't we

use Missouri granite?

At the time that the monument was being planned the only granite

quarry in Missouri was closed, and we were unable to negotiate to

obtain rock from this site.

Although we received considerable help

from the Missouri Department of Natural Resources, we were unable to

find an alternative site from which we could economically have

obtained the rock.

Back to Top

How was the original

rock cut, and was this done the same way?

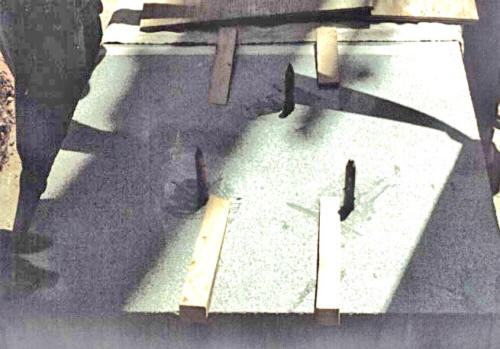

Figure 4. Wedges

driven along the bedding of a block to split it.

The original Stonehenge is made of

varieties of sandstone rock.

This rock has a clear bedding plane to

it, so that it can be relatively easily split to form flat surfaces.

Mining in Britain had been going on for at least a thousand years

before Stonehenge was built, so that skilled miners would know how,

using round stone hammers (still remaining at the site) flint

chisels and deer antlers, to shape the stone.

Final carving to shape

was probably done by manually chipping the rock, after the rocks had

been moved into their final position. We surmise this from the

evidence of tools which were found at the site.

The rock for the UMR-Stonehenge was originally quarried by two

methods, one of which is not that much different from the original.

In this method a set of wedges is placed into a line of holes along

the line of break wanted. The wedges are then hit, in turn, with a

hammer and, in a short time, enough force builds up along the line

that the rock breaks.

When cuts must be made across the bedding, splitting won't work and

the rock was cut out using a flame cutting torch, something which

looks like but is much bigger than a normal oxy-acetylene torch.

These lances are up to 10 ft long, and can cut the granite at about

ten square feet of rock an hour.

They are very noisy and are now

being replaced in quarries by diamond impregnated wire cutting saws.

Figure 5. Slot being

cut into the solid rock with a thermal lance.

In modern quarrying the rock is broken

out from the solid in large blocks which are then split into smaller

pieces by line drilling.

At the time that the rock was quarried for

our Stonehenge, however, this practice was not common, and the rock

which we received was not cut into the more regular shapes which are

now produced from most quarries.

In fact, since this brochure was first prepared the technology has

changed again twice. The first change was to the use of diamond wire

sawing. In this method a hole is drilled along the back edges of a

cut and a long wire is threaded through the hole. At intervals

along the wire small beads of plastic are mounted, which contain

diamond particles. The wire is tensioned and formed into a loop,

which is continuously pulled through the cut.

This creates a very narrow cut (which

increases the amount of quality granite produced) and leaves a very

smooth surface which can be used as one of the edges of the stone,

whereas with the earlier methods the edge had later to be removed.

(The latest method will be discussed later).

Those earlier methods

left the rock which we received in Rolla in a ragged shape.

Figure 6. Typical

shape of the rock blocks as received at Rolla.

Once the rock was brought to Rolla a

then novel method of mining, pioneered at UMR, was used to cut the

rock.

Water was pressurized to 15,000 psi (7.5 tons to the square

inch) and forced through a cutting lance fitted with two small

holes, each about 0.04 inches wide (about the size of the wire in a

paperclip).

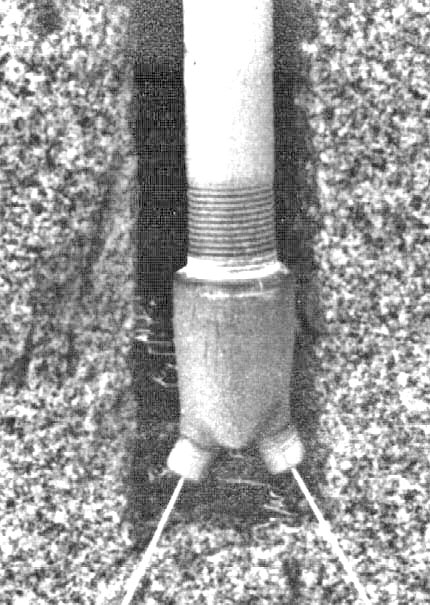

Figure 7. Cutting

nozzle, showing the jets at low pressure.

These jets are spun, at a speed of 180

rpm and the whole cutting assembly moves over the rock at a speed of

10 ft/min.

As the jets hit the rock, they cut a slot between a

quarter and a half inch deep and two inches wide. The cutting lance

is then lowered this amount, and moved back over the slot. A frame

was erected at the Rock Mechanics and Explosives Research Center to

cut the rock.

It was assembled from wooden ties and

radio antenna mast sections and provided a base along which the

cutting lance was moved. A wire mesh screen was fitted around the

frame to protect the operator from the small pieces of flying rock

which were removed by the jets during the cutting process.

The

cutting lance was pulled along the frame using a bicycle chain, and

two small hydraulic motors were used, one to turn the nozzle

assembly, and the other to draw it along the rock surface.

During the course of the rock cutting

the jets were able to cut an average of sixteen square feet of rock

an hour. The generator used to power the entire operation used

between four and six gallons of fuel an hour.

Figure 8. Cutting

Frame used to carve the individual rocks.

In this way a relatively straight cut

can be made on the rock surface without further damage to the rock.

You can see the lines left by individual passes of the jets on some

of the rocks.

Figure 9. Carved

blocks for the North trilithon legs.

The base of the analemma stone was left

partially uncut so that future generations could see how it was done

(although it is buried under the current ground level). The lower analemma stone sits on a concrete pad and has two slots in its base,

so that it can be re-leveled if necessary.

The organizing committee felt that this

was an important consideration, when it is recognized that Missouri

contains a fault at New Madrid which caused one of the largest

earthquakes in recorded American history.

It will be easier to

re-align the smaller analemma blocks, rather than the trilithons,

after the next such earthquake.

Figure 10. Detail of

the lower analemma stone, before it was covered by soil.

UMR-Stonehenge is the first major

structure to be carved using high pressure waterjets, it marks the

transition from mechanical excavation of rock to hydraulic

excavation and thus is a major mining milestone.

The monument was carved by a group now known as the High Pressure Waterjet Laboratory within the

Rock Mechanics and Explosives

Research Center at UMR. Under the overall direction of Dr. Summers

the day-to-day work was supervised by Dr. Marian Mazurkiewicz and

carried out largely by a group of undergraduate students.

The rock

was moved around during the cutting process using a crane.

Figure 11. The final

group of students who completed the rock cutting

(Dr. Mazurkiewicz

is at the right and Mr. Gabriele who provided the crane service is

at the back).

Back to Top

How did

the ancients move their rock, and how did they and UMR get the rocks

aligned so accurately?

Figure 12. Dr Senne

checking the alignment of the Trilithons.

The rocks for the original Stonehenge

were brought anywhere from 20 to 200 miles to the site.

Contrary to

popular myth, it is unlikely that vast teams of men hauled the rocks

all the way. While it would take some 700 men to pull one rock a

mile a day, oxen of that period could pull between 1,200 and 4,000

lbs each a distance of 20 miles a day, so that a span of 15 to 50

animals could have made the transport much easier and quicker.

The rocks would then be raised up a ramp and lowered into position.

By sharpening the bottom of the stones a little, it was then

possible to "walk" them into their final position. Final carving to

exact shape was completed after the stones had been erected.

For UMR-Stonehenge, the rocks were brought to UMR by truck and rail.

They were carved to shape at the Rock Mechanics and Explosives

Research Center and then brought to the site by truck.

Figure 13. Using a

crane and straps to position one of the Trilithons.

It took over four hours to get each rock

accurately aligned.

The great trilithon ring is set on an 18 in.

thick concrete pad and each rock was set on this. Straps were tied

around the center of each stone to lower them into place, and they

were then held in position using wooden braces until they could be

accurately aligned and set in the concrete.

Wedges were then driven under the

smaller stones (shims had to be set under the larger ones after

lifting it with the crane) until they were level.

Figure 14. Adjusting

the block alignment with a wedge.

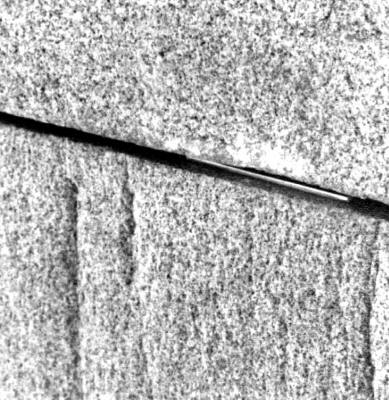

For the analemma stones where accuracy

is critical, the rock angle was first measured, (it was 89.5 deg)

and to ensure accuracy, 3 pins were set between the two rocks, while

a shim 1/16 in. thick was placed under the back of the upright

stone.

The upright was set the first time it

was placed. The gap between the stones was then sealed with resin.

Figure 15. The three

pins used to align the anelemma stones.

Each rock was aligned by Dr. Senne who

used the UMR computer to accurately identify the position of the

stones.

Each stone was set, in turn, on the 18

inch thick concrete slab, which runs underneath the entire assembly

of the five main trilithons.

Figure 16. The small

brass wedge used to align the analemma.

Figure 17. South Trilithon Legs braced in position while the

concrete sets.

Another 18 inches of concrete was then

poured around each stone to hold it in place, and a wooden

scaffolding was used to hold the rock in place until the concrete

set.

Back to Top

|