|

|

|

13 December 2010 from NatureAsia Website

An aqueous lithium-ion battery can be

recharged a thousand times with marginal capacity loss.

In contrast, the lithium-ion batteries typically found in laptops and mobile phones can pack a large amount of energy into a small space, and continue to work well after thousands of recharging cycles.

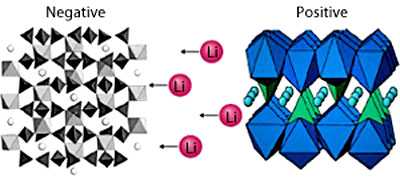

Lithium-ion batteries in which lithium ions are transported between the positive and negative electrodes through an aqueous solution could be used to power electric vehicles.

This recharge capacity comes at a cost,

however, because the flammable organic solvent used in lithium-ion

batteries to carry electrical current between electrodes makes the

batteries relatively expensive and somewhat explosive - factors that

have prevented larger lithium-ion batteries from being used in

vehicular applications.

This technology could enable much larger lithium-ion batteries to be used safely in electric vehicles.

As the battery charges, lithium ions are

added to the negative electrode, which is made from lithium titanium

phosphate. On discharging, lithium ions leave this electrode and

travel through the electrolyte - in this case an aqueous solution of

lithium sulfate - before inserting into the positive electrode,

which is made from carbon-coated lithium iron phosphate.

Operating at 1.4 V, the battery could be

completely charged and discharged a thousand times with only 10%

loss in capacity.

The

scientists are now developing ways to prevent the generation of

oxygen in the battery when it is overcharged by limiting the maximum

voltage of the positive electrode.

Reference

|