|

05 December 2011

from

NatureAsia Website

Computer simulations predict new carbon

materials that are stiffer than carbon nanotubes and tougher than

diamond.

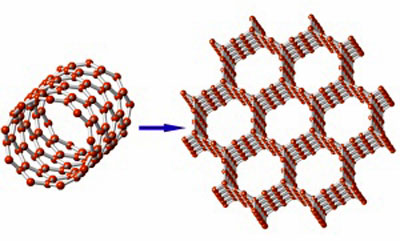

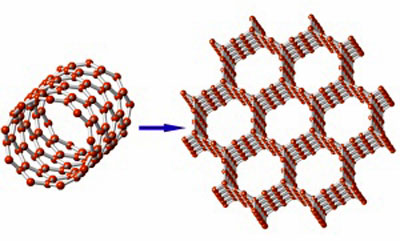

Bonding carbon

nanotubes (left) together into 3D arrays (right)

results in nanotube

polymer structures with remarkable mechanical and electronic

properties.

Carbon nanotubes are known for their

remarkable mechanical and electrical properties - but can these

properties be improved upon?

Calculations by Yongjun Tian and

colleagues from Yanshan University and Nankai University in China

have now shown that three-dimensional (3D) arrays of nanotubes could

have strikingly enhanced mechanical and electronic properties.1

Tian and his team used a computational approach to predict the

properties of the carbon-based materials that could be made if

arrays of carbon nanotubes could be bonded side-by-side to form a

three-dimensional polymer structure (above image). Their calculations

suggest that such materials should be quite possible to make, and

that they would have provide some important improvements to the nanotubes’ properties.

Of the eight structures predicted by the simulations, seven would be

‘superhard’ materials. Individual nanotubes are very stiff and

strong in the axial direction, but weak in the radial direction - a

factor that limits their application as structural materials.

However, the superhard 3D carbon

nanotube polymers are strong in both directions.

“Most of the nanotube polymers

combine this superhardness with good ductility, which gives them

the capability of resisting large strains without fracturing,”

says Tian. “They could be more resilient than diamond.”

In addition to the mechanical

enhancements, the 3D nanotube polymers also displayed some

surprising electronic characteristics.

Five of the polymers simulated only

conduct electrons along particular parallel and isolated one- and

two-dimensional channels due to the layout of the carbon-carbon

double bonds within the material.

“Another notable property is their

low density,” notes Tian. “These porous nanotube polymers have

potential uses as hydrogen-storage materials, shape-selective

catalysts, molecular sieves and absorbents.”

In order to tap into the properties of

these materials, the next step will be to make them.

Tian’s calculations predict that the

nanotube polymers should be more stable than carbon ‘buckyballs’,

and more stable than their parent nanotubes in some cases.

In fact, such structures have probably

been created before as unintended by-products in the synthesis of

other novel carbon materials, and simply never isolated.

“The next step is to explore

approaches to synthesize this class of 3D nanotube polymers,

including high-pressure polymerization and chemical reactions,”

says Tian.

Reference

-

Zhao, Z. S.1, Xu, B.1, Wang,

L.-M.1, Zhou, X.-F.2, He, J. L.1, Liu, Z. Y.1, Wang, H.-T.2

& Tian, Y. J.1 Three dimensional carbon-nanotube polymers.

ACS Nano 5, 7226 (2011). |

article

Author affiliation

1. State Key Laboratory of

Metastable Materials Science and Technology, Yanshan

University, Qinhuangdao 066004, China

2. School of Physics and Key Laboratory of Weak-Light

Nonlinear Photonics, Ministry of Education, Nankai

University, Tianjin 300071, China

|